High speed silicon wet anisotropic etching for applications in …

2021年2月22日 · Wet anisotropic etching is extensively employed in silicon bulk micromachining to fabricate microstructures for various applications in the field of microelectromechanical …

Isotropic wet etching: For isotropic wet etching, a mixture of hydrofluoric acid, nitric acid, and acetic acid (HNA) is the most common etchant solvent for silicon. The concentrations of each …

The degree of anisotropy (= etch rate selectivity between different crystal planes), the etch rates, and the etching homogeneity depend on the etching temperature, atomic defects in the silicon …

Wet etching is a process in which chemical solutions, or etchants, are used to dissolve areas of a silicon substrate that are unprotected by an etching mask. The two different types of wet …

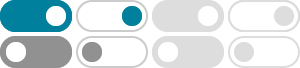

Wet chemical etching can be isotropic or anisotropic (Fig. 1). Isotropic etchants have the same etch rate for all crystal planes. Anisotropic etchants favor one crystallographic plane over …

Wet anisotropic etching characteristics of Si{111} in NaOH-based ...

2022年12月1日 · Wet anisotropic etching is a popular technique to perform silicon micromachining as it is low-cost, scalable, and suitable for large scale batch processing, which are the major …

Wet Etching of Quartz • Anisotropic etching by HF – with 10.9mol/l, Rate ~ 9.6 µm/hr • Ammonium fluoride (NH4F) • Saturated ammonium bifluoride (NH4HF2) • Require metal mask or oxide …

Isotropic and Anisotropic Silicon Wet Etching Processes

2023年5月23日 · Anisotropic silicon wet etching is a process that selectively removes material from a silicon substrate in one direction, creating well-defined features with sharp corners and …

Anisotropic Etching - SpringerLink

Anisotropic etching is a subtractive microfabrication technique that aims to preferentially remove a material in specific directions to obtain intricate and often flat shapes. Wet techniques exploit …

Why Wet Anisotropic Etching? Why Not Wet Anisotropic Etching?